Things about Sheroz Earthworks

Table of ContentsThe 9-Minute Rule for Sheroz EarthworksNot known Details About Sheroz Earthworks All About Sheroz EarthworksEverything about Sheroz EarthworksGet This Report about Sheroz EarthworksSheroz Earthworks Can Be Fun For Everyone

Today, Smart Building and construction Remote connects over 700 machines on jobsites to workplaces, conserving hundreds of hours formerly spent by jobsite supervisors, surveyors and designers travelling from workplaces to jobsites. So to sum up, the very first 10 years of Komatsu's smart machine control have actually been marked by a years of one-of-a-kind innovation, continuous learning and development with clients.Below's to the following 10 years! Material created in organization with Komatsu.

In the swiftly evolving globe of building, accuracy and effectiveness are essential. 3D equipment control, a system that utilizes general practitioner and various other sensors to lead equipment with pinpoint accuracy, is changing the sector - https://myspace.com/sherozau. From its very early days of 2D advice, this innovation has actually progressed substantially, making tasks that once called for hands-on treatment currently feasible with marginal human input

In construction, it makes sure that every cut, fill, and quality is implemented with medical precision. Let's explore how this game-changing technology works. At the core of any type of 3D equipment control system are GNSS receivers and antennas, recording satellite signals to establish the maker's exact place. Onboard computer systems and control boxes process this information and communicate with the machinery.

Little Known Facts About Sheroz Earthworks.

This includes establishing up GNSS receivers, adjusting sensors, and configuring the equipment control software - trimble gps. The magic of 3D device control exists in its real-time data collection and processing.

Interface supply real-time updates on the equipment's position and needed modifications, making certain accurate control. Several variables impact accuracy, including satellite signal quality and sensor calibration. Strategies like Real-Time Kinematic (RTK) placing and Precise Point Positioning (PPP) boost accuracy, making sure the highest accuracy. In building, 3D equipment control is made use of for earthmoving, grading, paving, and excavation, making sure jobs are finished to exact specs.

Getting My Sheroz Earthworks To Work

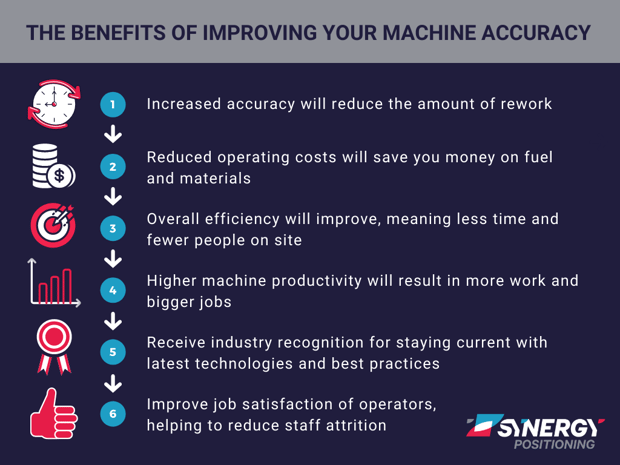

3D equipment control considerably raises effectiveness by reducing rework and reducing product waste, bring about much faster and more affordable job conclusion. The innovation guarantees every task is carried out exactly as intended, causing continually high-grade job. Among one of the most compelling advantages of 3D machine control is the considerable expense savings it uses.

Fuel consumption is optimized due to the fact that machines operate more efficiently and avoid unnecessary movements. Upkeep prices are likewise decreased, as the equipment experiences much less deterioration because of specific procedure. Overall, these financial savings add to a much more successful lower line for any type of job. By lowering human mistake and limiting exposure to unsafe environments, 3D device control improves employee security and reduces accidents.

From building to mining, this innovation makes certain tasks are implemented properly and securely, reducing costs and enhancing results. As innovations proceed, the capacity for 3D machine control to additionally boost efficiency and security grows. Welcoming this technology is vital for industry professionals aiming to remain affordable and accomplish the greatest standards in their jobs.

The Only Guide for Sheroz Earthworks

Discover the future of accuracy and efficiency currently! Check out our latest YouTube video on the FJD H36 Electric Motor Control System to see the innovation in action: View now.

Throughout the years, we've seen drivers with great deals of experience do some amazing points with their makers. Perhaps they have an eye for adjustments that boost accuracy, or possibly they recognize which attributes of their equipment to use and when to increase performance or effectiveness - https://www.wattpad.com/user/sherozau. With today's developments in heavy equipment technology, even proficient drivers can benefit from a real-time assist to boost their daily efficiency.

This is where device control systems aspect in. A system with an in-cab tablet computer that incorporates sensing units and general practitioners modern technology can sustain precision and performance. Volvo Construction EquipmentLet's look at excavators as our first example. Some excavators feature machine control systems that guide the operator via features to automate the excavating procedure.

Examine This Report about Sheroz Earthworks

With this added accuracy, rework is basically gotten rid of, permitting the driver to finish the project on schedule and transfer to the following task. For those working with hazardous or hard jobsites, remote-controlled options open new chances. This impressive add-on allows you to operate an excavator from a range in areas with dangerous compounds (like in a potash mine) or bad ground problems (like mud).

Maker control systems supply important advantages to even more than just excavator drivers. If you have actually a truck come in with a target of 23 loads, your driver can load their pail and dynamically weigh itoften without even being fixed.

This means the operator can see the precise weight of the tons they're concerning to dispose (fj dynamics autosteer review). On-board weighing supplies real-time understanding right into the pail's load to make overloading, underloading, reweighing and waiting times a thing of the past. Volvo Construction EquipmentIf they unload 12 lots on the very first pass, the following container requires to evaluate 11 lots

The 45-Second Trick For Sheroz Earthworks

A lot of operations use an on-board evaluating application to guarantee that the lots is accurate before they send their vehicles to the ranges, which is essential since the scale weight is what's made use of for payment and invoicing functions. A number additional hints of producers include some kind of weighing program on their loaders. Some also have attributes that permit business to check and control the complete lots of multiple trucks.